Introduction

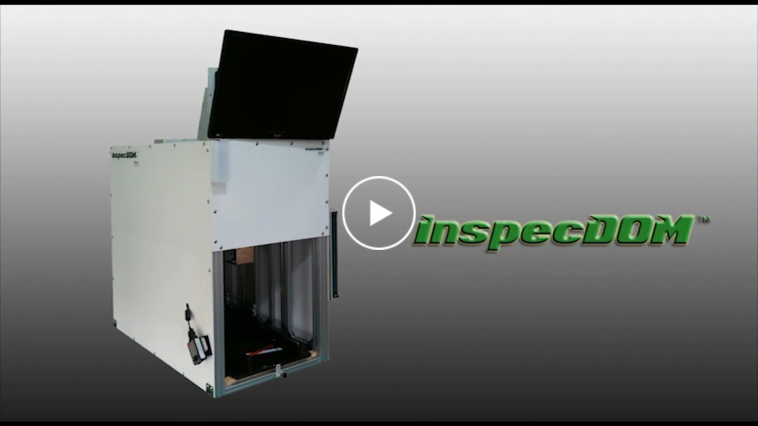

InspecDOM™ is suitable for “Plastic Automotive Parts”, small quantity batch productions.

InspecDOM™ is able to enroll a lot of new inspection models & easily change inspection settings (areas, conditions, etc.).

Key Features

〮 Wide Coverage : can cover plastic automotive parts with various shape, size, etc..

〮 Flexible Usage : can inspect a lot of different of objects just by changing Jigs.

〮 Powerful Software : can detect wrong-assembled product, short shot(incompleted product), distortion, measurement, etc..

〮 User-friendly Design

〮 Easy to Use & Maintain

〮 Various Option (Manual / Automatic Loading, Barcodes Reader, etc.)

〮 Reasonable Price

Details

〮 Technical Data – H/W

– Specification (e.g. InspecDOM™ – SA / changeable depending on the initial design).

| Name | InspecDOM™ |

| Dimension (mm) | 500 x 700 x 750 (Wide x Length x Height) |

| Weight (kg) | More than 70 |

| Inspection Area (FOV) | 260 x 460 (with 2 cameras) |

| Position of Camera | Standard : 2 cameras located upper side of product Option : Special camera can be added for an oblique surface. |

| Inspection Resolution | Standard Camera : about 150 x 150 ㎛ Special Camera : less than 150 ㎛ |

| Electric Power (kw) | less than 5 Kw / single phase 220 V |

| Luminous Intensity (lux) | more than 4000 |

| Inspection Speed | within 2 sec after stable loading |

| Inspection Result | Pass : Green light, “Pass” sound file Fail : Red light, Warning sound file, “Fail” position showed in monitor |

– H/W Block Diagram

〮 Technical Data – S/W

– S/W Block Diagram

– S/W Scenario

〮 Case Study – Plastic Automotive Parts Assembly